27 years of professional customized gear transmission manufacturers, high-speed teeth, bevel gears for 10 consecutive years into the domestic gear industry top three, has been awarded 45 national invention and utility model patents

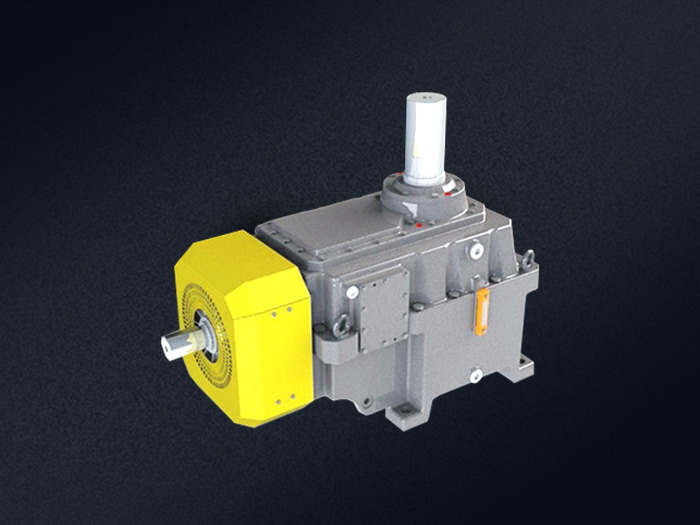

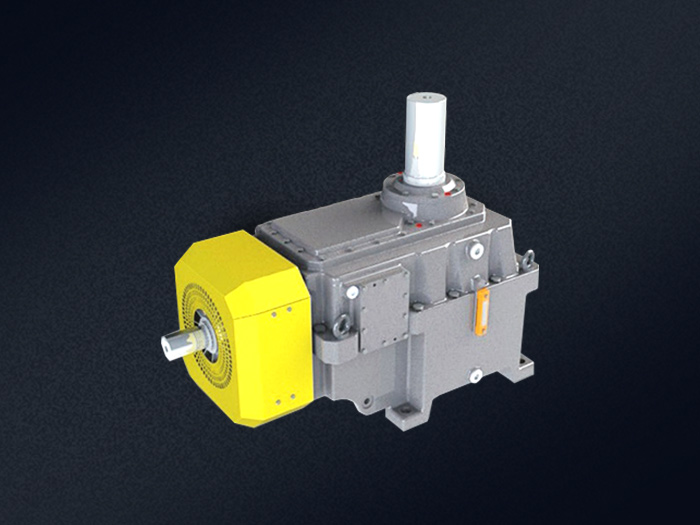

JS series gearbox is developed specifically for the characteristics of domestic underground coal mines, it features high reliability, easy maintenance, and high efficiency and energy saving. Developed specifically for the characteristics of domestic underground coal mines, it features high reliability, easy maintenance, and high efficiency and energy saving.

ConsultingApplication Area: Metallurgical Mining

Product features: Modular design, compact structure; high operational efficiency; suitable for heavy-duty and high-dust environments